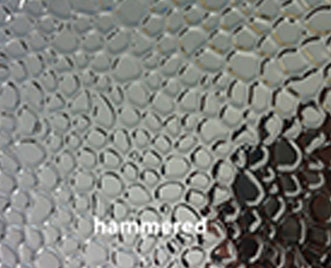

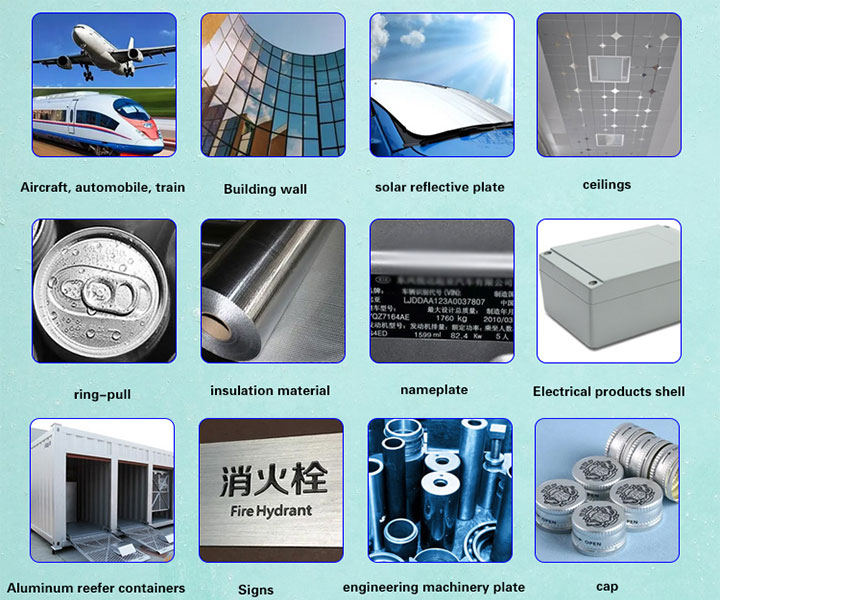

Color coated aluminum coil is often used in the decoration industry. The exquisite surface and excellent quality of color coated aluminum coil have become the primary choice of users in many fields

We supply OEM service ,customize color and pattern

We can accept any third party inspection

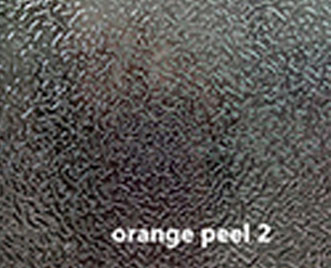

Orange peel aluminum coil is made by placing aluminum coil in corresponding electrolyte and electrolyzing under specific conditions and external current. Orange peel aluminum coil surface formed a thin layer of aluminum oxide, thickness of 20 microns. Orange peel aluminum coil improves hardness and wear resistance, hard oxide film melting point is relatively high. The stucco-like orange pattern surface texture hides small imperfections and scratches caused by physical damage during or after installation. This finish also reduces reflectivity while still looking very professional. Lastly, the use of stucco embossed finish provides a small increase to the rigidity and strength of the aluminum jacketing.Most common models are 1100,1060 ,3003 and etc.

Orange peel aluminum coil is made of aluminum plate and aluminum coil pressed by embossing equipment. Embossed aluminum plate and aluminum coil are used in equipment anticorrosion and heat preservation, pipeline anticorrosion and heat preservation, refrigerator and air conditioning accessories and so on.

Orange peel aluminum roll thickness directly affects the service life of aluminum roll, especially in embossing is easy to fall off, the appearance of the product quality has a great impact, can reduce the service life, but also pay attention to plate control, pull bending straighten clean, otherwise the adhesion is small.

| Alloy | 1060 1100 1070 1050 |

| Temper | H24/34 |

| Thickness | From 0.7mm to 1.2 mm |

| Width | From 40 - 1600 mm |

| Diameter | Standard dia:1100mm Interior dia:150mm, 405mm, 505mm |

| Weight | 0.5 - 3.0 Tons per coil |

| Coating | PE / PVDF |

| Surface | Embossed, Coated, Pre-painted |

| Color | RAL Color System or Customized |

| Gloss | 3 - 110 (EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF: more than 25 micron |

| Coating Hardness(pencil resistance) | More than 2h |

| Coating Adhesion | 5J (EN ISO-2409:1994) |

| Impact Resistance | No peeling or cracking (50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | 90, 1T, 2T, 3T |

| MEK Resistance | More than 150 |

It is widely used in refrigerator, freezer , interior decoration ,roofing,ceiling,wall decoration, household appliances , and other fields.The products have all kinds of thickness,width and specification,which can sufficiently meet the user’s demand.Used for Insulation works,fridge freezer, cold storage, roofing panels, floor, building, electric, wall, machine and so on.

Anti-water paper and plastic+covered by iron sheet+ strapped with min three strapping strips+ fixed on the iron or wooden pallets by strapping strips.

Ship goods within 5 days after received deposit for stock goods ;

Customize size need about 10 days to ship;

OEM products need about 15 days to ship

Shipping by containers ;Shipping by bulk ship