Aluminum alloy pipe because of light weight, high strength, good corrosion resistance, non-magnetic, good formability and low temperature performance, is widely used in all kinds of welding structure products, using aluminum alloy instead of steel plate material welding, structural weight can be reduced by more than 50%. Therefore, aluminum and aluminum alloy are not only widely used in aviation, aerospace and electrical fields, but also more and more used in petrochemical industry.

Our company offers competitive price with good quality.

Samples can be provide for testing.

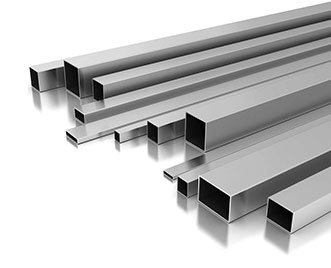

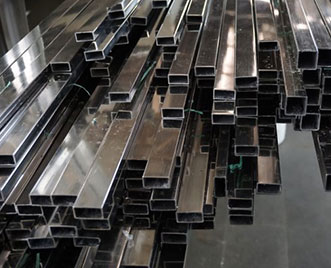

According to the aluminum pipe production mode, it is divided into seamless pipe and welded pipe.

In the welding process, aluminum and aluminum alloys are prone to oxidation pores, thermal cracks, burning through and collapse, which are the welding materials with great difficulty. Especially, it is more difficult to master the welding of small-diameter thin-walled pipe. Therefore, there are requirements on selection. And the parameters are stable, flexible adjustment and safe and reliable performance, but also should have arc starting, arc stabilizing and dc component elimination device, welding current, voltmeter should be qualified by the measurement department.

The welding site should be kept clean. In addition to windproof, rainproof and snow proof facilities, the relative humidity during welding should be no more than 80%, and the environmental temperature should be more than 5℃.

These above things mentions will be better for aluminum weld. 6

061 has excellent machining performance, good corrosion resistance, high toughness and no deformation after processing, easy coloring film, excellent oxidation effect and other excellent characteristics.

| Outer Diameter | 0.8mm-600mm or customer requirements |

| Wall thickness | 0.3-50mm or customer requirements |

| Length | 2.5meters or as customer's requirements |

| Standard | ASTM, ASME,EN, JIS, DIN,GB/T etc |

| Grade | 1070,1060,1050,1030,1100,2017,2024,2117,2014,2214,2618,2018,2218,2219,2021,3003,5052,5154,5083,5456,5056,6165,6061,6055,6063,7001,7178,7075, |

| Temper | T3-T8 |

| Surface | Flat , mill, bright, polished, hair line, brush,sand blast, checkered,embossed, etching , |

| Shape | Round/Square/Rectangular /Oval |

| Sample | Free sample fee |

| Back lamination | polykraft paper, polysurlyn, kraft paper, craft paper |

| Inspection | SGS,or other Third Party inspection |

| Payment | T/T, L/C,Western Union, |

| Pyaterm | EXW,FOB,CIF,CFR |

| Package | PVC+ waterproof paper + strong sea-worthy wooden package |

| Aluminum alloy | Grade | Normal | Temper | Tensile Strength | Yield Strength | Elongation% | Brinell Hardness | |

| Temper | σ B (MPa) | σ0.2 (MPa) | Plate | Bar | HB | |||

| Pure Al 1XXX | 1050 | O,H112,H | O | 78 | 34 | 40 | - | 20 |

| 1060 | O,H112,H | O | 70 | 30 | 43 | - | 19 | |

| Al-Cu | 2019 | O,T3,T4,T6,T8 | T851 | 450 | 350 | 10 | - | - |

| (2XXX) | 2024 | O,T4 | T4 | 470 | 325 | 20 | 17 | 120 |

| Al-Mn | 3003 | O,H112,H | O | 110 | 40 | 30 | 37 | 28 |

| (3XXX) | 3004 | O,H112,H | O | 180 | 70 | 20 | 22 | 45 |

| Al-Si (4XXX) | 4032 | O,T6,T62 | T6 | 380 | 315 | - | 9 | 120 |

| Al-Mg | 5052 | O,H112,H | H34 | 260 | 215 | 10 | 12 | 68 |

| (5XXX) | 5083 | O,H112,H | O | 290 | 145 | - | 20 | - |

| Al-Mg-Si | 6061 | O,T4,T6,T8 | T6 | 310 | 275 | 12 | 15 | 95 |

| (6XXX) | 6063 | O,T1,T5,T6,T8 | T5 | 185 | 145 | 12 | - | 60 |

| Al-Zn-Mg | 7003 | T5 | T5 | 315 | 255 | 15 | - | 85 |

| (7XXX) | 7075 | O,T6 | T6 | 570 | 505 | 11 | 9 | 150 |

Aluminum alloy welded pipe is widely used in the frame of building aluminum doors, Windows and curtain walls. It is a common aluminum alloy model. At the same time welded pipe can be used in decorative pipe, industrial pipe, some shallow tensile products.

Exprot sea worthy package and water proof paper and wooden pallet with Safe loading and fixing Professional teams

Ship goods within 5 days after received deposit for stock goods;

Customize size need about 10 days to ship;

OEM products need about 15 days to ship

Shipping by containers ;Shipping by bulk ship