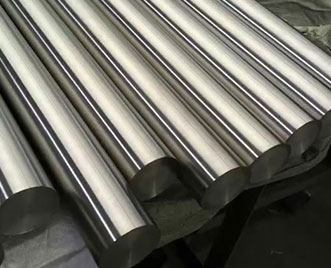

Diameter: 6mm-800mm or as the customer’s request

Length: 2m,3m,5.8m,6m, or as the customer’s request

Material: 1060,1050,1100,2024,2124,3003,3004,3A12,5052,5652,5154,5254, 5454,5083,5754,5086,5056,5456,5A02,6061,6062,6063,7075,8011,etc.

Quality control: Mill Test Certification is supplied with shipment,Third Part Inspection is acceptable.

2214 is a kind of hard aluminum with high strength, which can be strengthened by heat treatment. It has medium plasticity in annealing, hardening and hot states, and good weldability in spot welding. It has a tendency to form intergranular cracks when it is used in gas welding and argon arc welding. The machinability of the alloy is good after quenching and cold work hardening, but poor after annealing. Corrosion resistance is not high, often using anodic oxidation treatment and paint method or surface coated with aluminum layer to improve corrosion resistance.

The density of 2214 is 2.78(g/cm3). And according to GB/T3190-98 T1/T2/T3/T4/T6/T8/T9/T351/T651/O. The chemical composition of 2A12:Si≤0.50,Cu:3.8-4.9;Mg:1.2-1.8;Zn:≤0.30;Mn:0.30-0.9;Ti:≤0.15;Ni+Fe:≤0.10-0.5.

Mechanical property of 2A12:

Weld-ability -- restricted

Mach-inability -- very good

Corrosion resistance -- poor

Electrical conductivity of 20 ℃ (68 ℉) - 30-40(%IACS)

Density (20 ℃) - 2.78 (g/cm3)

Tensile strength (25°C MPa)-- 472

Yield strength (25°C MPa)-- 325

Hardness (500kg force 10mm ball)-- 120

Elongation (1.6mm(1/16in) thickness) --10

Maximum shear stress (MPa)-- 285.

| Diameter | 6-800mm or customer requirements |

| Length | 2m,3m,5.8m,6m,as customer's requirements |

| Grade | 1070,1060,1050,1030,1100,2017,2024,2117,2014,2214,2618,2018,2218,2219,2021,3003,5052,5154,5083,5456,5056,6165,6061,6055,6063,7001,7178,7075, |

| Temper | HO,H12,H14,H16,H18,H19,H22,H24,H26,H28,F,H112,T651,T3,T451,T4,T6,ect |

| Surface | Flat , mill, bright, polished, hair line, brush,sand blast, checkered,embossed, etching , |

| Form | coil,sheet,profiles,bar,tube,casting |

| Sample | Free sample fee |

| Back lamination | polykraft paper, polysurlyn, kraft paper, craft paper |

| Inspection | SGS,or other Third Party inspection |

| Payment | T/T, L/C,Western Union, |

| Pyaterm | EXW,FOB,CIF,CFR |

| Package | PVC+ waterproof paper + strong sea-worthy wooden package |

| 2***series Chemical composition(%): | ||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni | Al |

| 2014 | 0.2 | 0.7 | 3.9-4.8 | 0.9 | 0.4-0.8 | - | ≤0.3 | ≤0.15 | ≤0.1 | Remains |

| 2017 | 0.2-0.8 | 0.7 | 3.5-4.5 | 0.4-1.0 | 0.4-0.8 | 0.1 | 0.25 | ≤0.15 | - | Remains |

| 2219 | 0.2 | 0.3 | 5.8-6.8 | 0.2-0.4 | 0.02 | - | 0.1 | 0.02-0.1 | - | Remains |

| 2618 | 0.5 | 0.7 | 3.8-4.3 | 0.5-1.0 | 1.7-2.3 | - | 0.1 | 0.03-0.15 | - | Remains |

| 2018 | 0.9 | 1.0 | 3.5-4.5 | 0.2 | 0.45-0.9 | 0.1 | 0.25 | - | 1.7-2.3 | Remains |

| 2218 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | - | - | - | - | Remains |

| 2214 | 0.5-1.2 | 0.3 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | - | Remains |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | - | Remains |

| Diameter | |||||

| Special size | Ø4mm | Ø7mm | Ø9mm | Ø11mm | Ø13mm |

| Commom size | Ø5mm | Ø6mm | Ø8mm | Ø10mm | Ø12mm |

| Ø14mm | Ø15mm | Ø16mm | Ø18mm | Ø20mm | |

| Ø22mm | Ø25mm | Ø26mm | Ø28mm | Ø30mm | |

| Ø35mm | Ø40mm | Ø45mm | Ø50mm | Ø55mm | |

| Ø60mm | Ø65mm | Ø70mm | Ø75mm | Ø80mm | |

| Ø90mm | Ø100mm | Ø110mm | Ø120mm | Ø130mm | |

| Ø140mm | Ø150mm | ||||

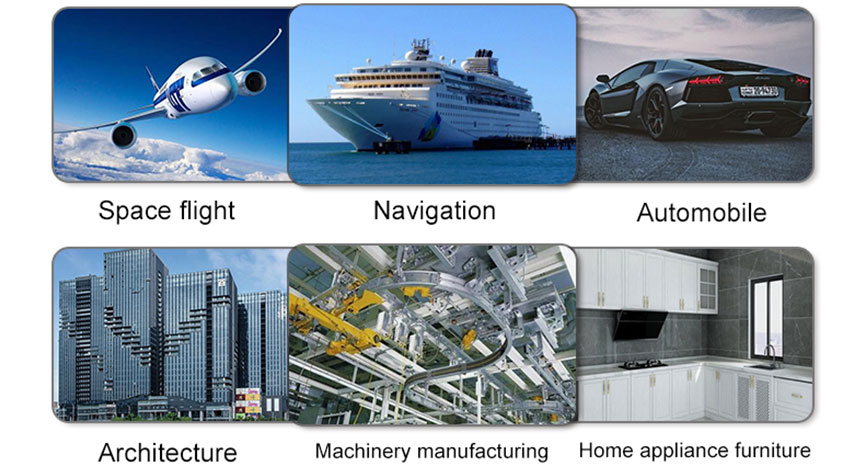

2214's alloying element is copper, known as duralumin, which has high strength and good machinability but poor corrosion resistance,so that are used in high strength and hardness (including high temperature) occasions. Heavy forgings, thick plates and extruded materials are used for aircraft structures, first-stage rocket fuel tanks and spacecraft parts, wheels, truck frames and suspension parts.

Exprot sea worthy package and water proof paper and wooden pallet with Safe loading and fixing Professional teams

ship goods within 5 days after received deposit for stock goods;

Customize size need about 10 days to ship;

OEM products need about 15 days to ship;

Shipping by containers ;Shipping by bulk ship