Aluminum coil ‘s thickness:0.1mm-10mm.

Anti-corrosion and rust special aluminum coil’s thickness:0.3mm-3mm.

Aluminium coil for power plant’s thickness0.5mm,0.6mm,0.75mm,0.8mm.

Color coated aluminium coil/Embossed aluminum coil’s thick:0.2mm-1.2mm.

Have plenty of inventory,can delivery within 7days.

We can accept any third party inspection.

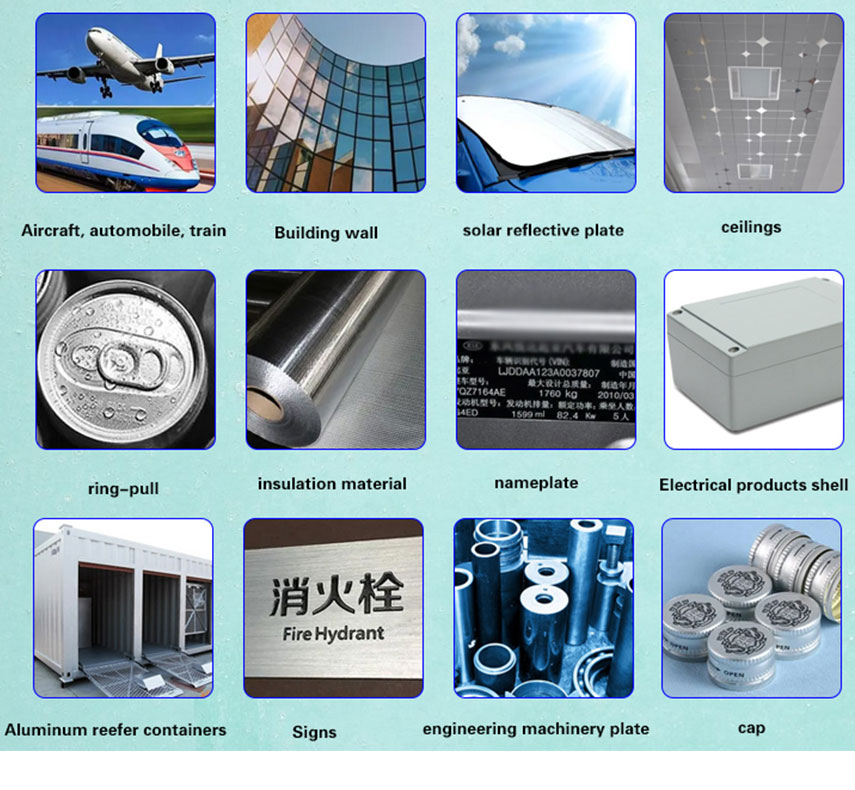

According to GB/T3190-1996, the 1050 pure aluminum up to 99.5%.1050 is industrial pure aluminum, with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not strengthen the machinability is not good; Gas welding, hydrogen welding and contact welding, not easy to braze; Easy to withstand all kinds of pressure processing and extension, bending.

And the 1050 coil’s chemical component:

Al:99.5%;Si:≤0.25;Cu:≤0.05;Mg:≤0.05;Zn:≤0.05;Mn:≤0.05;Ti:≤0.03;V:≤0.05;Fe:0.4

Heat treatment regime:

(1)Complete annealing: heating 390 ~ 430℃; The insulation time is 30 ~ 120min depending on the effective thickness of the material. At the speed of 30 ~ 50℃/h, the furnace is cooled to 300℃, and then air cooled.

(2)Rapid annealing: heating 350 ~ 370℃; The insulation time is 30 ~ 120min depending on the effective thickness of the material. Air or water cooling.

(3) Quenching and aging: quenching 500 ~ 510℃, air cooling; Artificial aging 95 ~ 105℃,3h, air cooling; Natural aging room temperature 120h.

| Thichness | 0.1mm-10mm |

| Width | 19mm-2650mm |

| Length | as customer's requirements |

| Grade | 1070,1060,1050,1030,1100,2017,2024,2117,2014,2214,2618,2018,2218,2219,2021,3003,5052,5154,5083,5456,5056,6165,6061,6055,6063,7001,7178,7075, |

| Temper | HO,H12,H14,H16,H18,H19,H22,H24,H26,H28,F,H112,T651,T3,T451,T4,T6,etc |

| Surface | Flat , mill, bright, polished, hair line, brush,sand blast, checkered,embossed, etching ,spray paint, electroplate, anodic oxidation, infiltration, oil spraying, sand blasting |

| Sample | Free sample fee |

| Back lamination | polykraft paper, polysurlyn, kraft paper, craft paper |

| Inspection | SGS,or other Third Party inspection |

| Payment | T/T, L/C,Western Union, |

| Pyaterm | EXW,FOB,CIF,CFR |

| Package | PVC+ waterproof paper + strong sea-worthy wooden package |

In the process of cold rolling aluminum coil, due to the friction and pressing between the roller and the surface of aluminum plate, the surface of aluminum oxide powder will fall off and adsorption, rolling oil and its attached suspended components will remain on the surface of aluminum coil, which will adversely affect the processing of aluminum coil composite, coating and other finished products. Due to the severe bending deformation of the strip on the roller, part of the tension exerted on the strip is converted into the pressure of the strip on the tension roller, and finally forms the friction force to drive the roller set. If the surface of the alumina roll is not cleaned, the alumina powder falls off when it is deformed, and it is attached to the roller surface of the tension roller with oil pollution, so that the roller surface is worn, and the aluminum plate is slightly damaged, so it must be cleaned by a special cleaning device.

Anti-water paper and plastic+covered by iron sheet+ strapped with min three strapping strips+ fixed on the iron or wooden pallets by strapping strips.

Ship goods within 5 days after received deposit for stock goods ;

Customize size need about 10 days to ship;

OEM products need about 15 days to ship

Shipping by containers ;Shipping by bulk ship